CNC Milling China: Driving Global Precision Manufacturing

Precision at Scale

In the evolving landscape of global manufacturing, the demand for accuracy, consistency, and affordability has never been greater. Companies worldwide are constantly seeking ways to enhance their production quality while staying within budget. This is where CNC milling China emerges as a leading solution. With its blend of cutting-edge technology, skilled labor, and cost-effective production models, China has become a global hub for CNC milling services.

What Is CNC Milling?

CNC milling is a subtractive manufacturing process where material is removed from a solid block (or workpiece) using a rotating cutting tool. This process is computer-controlled, allowing for high levels of accuracy and repeatability. CNC (Computer Numerical Control) systems translate digital designs into precise machine commands, ensuring that even complex geometries are executed flawlessly.

CNC milling is used for producing everything from mechanical components and prototypes to end-use products across various industries including automotive, aerospace, electronics, and medical devices.

Rise of CNC Milling in China

China’s journey in CNC milling began decades ago, but recent technological advancements have significantly accelerated its growth. With increased investment in cnc milling china robotics, automation, and AI-driven machinery, Chinese manufacturers now offer services that rival and, in many cases, exceed the quality standards of Western countries.

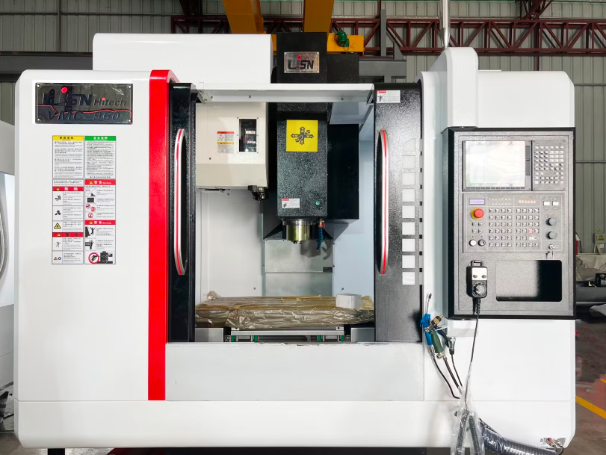

One key advantage of choosing CNC milling China is the integration of affordable production with cutting-edge infrastructure. Factories are equipped with 3-, 4-, and 5-axis milling machines capable of producing parts with extremely tight tolerances. This combination of scale and precision has made China a go-to destination for businesses around the world.

Advantages of CNC Milling in China

Cost Efficiency

One of the primary reasons companies outsource to China is cost savings. This allows startups and established companies alike to access high-quality milling without inflating their budgets.

Advanced Technology

Contrary to outdated perceptions, many Chinese CNC factories are outfitted with state-of-the-art equipment and software. They often utilize globally recognized machine brands and CAD/CAM programs, ensuring compatibility with international standards.

Skilled Workforce

A significant factor behind the success of CNC milling in China is the availability of skilled machinists and engineers. These professionals are trained to operate complex machinery, interpret detailed blueprints, and perform rigorous quality checks—ensuring every product meets the client’s specifications.

Fast Turnaround

Due to streamlined operations and abundant resources, Chinese CNC milling companies can offer faster production cycles. For companies operating under tight schedules, this quick delivery is a crucial advantage.

Material Availability

China’s vast industrial network ensures easy access to various raw materials, from aluminum and stainless steel to specialized plastics and titanium. This availability reduces procurement time and cost, especially for custom or low-volume orders.

Industries Served

CNC milling China caters to a wide array of sectors. The automotive industry benefits from engine components, transmission cases, and precision gears produced with high consistency.

Read also: Why Buying a Franchise in Sydney is a Smart Business Move

Electronics firms depend on CNC-milled housings, connectors, and intricate components for devices. In the medical field, parts for surgical instruments and diagnostic equipment are milled with utmost precision to ensure safety and compliance with health regulations.

Quality Assurance

Quality control is a top priority among China’s leading CNC milling providers. Most reputable factories follow international certifications like ISO 9001, ISO 13485 (medical devices), and AS9100 (aerospace). This ensures that processes are standardized, documented, and regularly audited.

Inspection methods often include:

- Coordinate Measuring Machines (CMM) for 3D measurements

- Optical Comparators for profile and surface analysis

- Surface Finish Testing to meet application-specific needs

Before shipment, parts often undergo multiple quality checks, ensuring defects are caught early and customer satisfaction remains high.

Customization and Prototyping

China’s CNC milling ecosystem excels not only in mass production but also in prototyping and custom manufacturing. Whether it’s a single unit or a short run of precision parts, manufacturers are equipped to handle diverse requirements.

For designers and engineers in the development stage, this flexibility is crucial. It allows for quick iterations, testing, and finalizing of products before full-scale production begins. Most Chinese CNC companies offer DFM (Design for Manufacturability) feedback, helping clients refine their designs for optimal results.

Communication and Collaboration

Language and communication used to be a concern for overseas clients. However, modern Chinese CNC providers typically have English-speaking support teams, project managers, and engineers to ensure seamless collaboration.

Advanced platforms for file sharing, real-time updates, and project tracking have further reduced the communication gap. Clients can now upload CAD files, receive instant quotes, and monitor production timelines with ease.

Choosing the Right Partner

Not all CNC milling providers are created equal. To find the right partner in China, businesses should consider:

- Experience: Look for companies with a proven track record in your industry.

- Certifications: Ensure they meet the required international quality standards.

- Reviews and References: Ask for samples, testimonials, or client references.

- Facility Tour (Virtual or On-Site): Many suppliers offer virtual tours, which can help assess their infrastructure.

- Support Services: Ensure they offer post-production support, revisions, and packaging solutions.

Establishing a long-term relationship with a reliable Chinese CNC milling partner can offer substantial benefits in terms of both quality and cost.

Future Outlook

As automation and digitalization continue to evolve, CNC milling China is poised for even greater growth. Integration of smart factories, AI-powered machines, and sustainable practices is transforming the industry.

Final Thoughts

CNC milling in China represents a powerful blend of technology, talent, and cost efficiency. Whether you’re a small startup looking for rapid prototyping or a large corporation in need of high-volume precision parts, Chinese manufacturers offer an unmatched value proposition.

By leveraging CNC milling China, businesses can access world-class production capabilities, reduce operational costs, and remain competitive in a fast-paced global market. As long as companies choose their partners wisely and maintain clear communication, this collaboration can result in high-quality, consistent, and innovative manufacturing outcomes.