Rack and Pinion Manufacturer: Driving Innovation in Linear Motion Systems

From massive industrial machinery to compact robotics and modern steering systems, rack and pinion manufacturer are the unsung heroes that convert rotational motion into linear travel. While the mechanism itself is simple in theory, the production of high-performance, durable, and application-specific systems requires deep engineering expertise — a domain best served by a professional rack and pinion manufacturer.

In this comprehensive article, we’ll explore the core role of rack and pinion manufacturers, their capabilities, the industries they serve, how to choose the right manufacturer, and the technological innovations shaping this essential field.

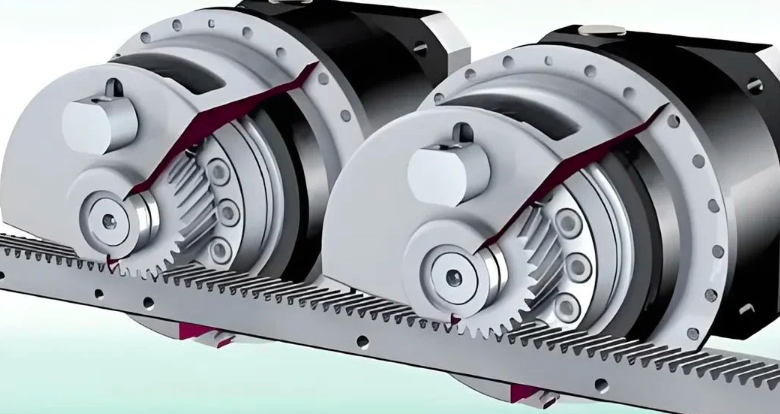

Understanding Rack and Pinion Systems

- The rack is a straight, toothed component.

The design is simple, but the implementation — especially in high-load or high-precision applications — requires sophisticated engineering and production capabilities that only an experienced rack and pinion manufacturer can offer.

Types of Rack and Pinion Systems

Before choosing a manufacturer, it’s important to understand the different configurations of rack and pinion systems:

1. Straight Rack with Spur Gear Pinion

The most common setup, used for general applications in machinery and transportation.

2. Helical Rack and Pinion

Offers quieter operation and better load distribution. Ideal for applications needing higher speed or smoother movement.

3. Split Rack and Pinion

Designed for eliminating backlash, often used in precision cutting machines or robotics.

4. Curved or Circular Rack Systems

Used in rotary motion applications such as radar, solar tracking, or turntables.

5. Custom Rack and Pinion Assemblies

Made to meet unique specifications in terms of pitch, material, length, and environmental conditions.

An expert rack and pinion manufacturer will offer all these varieties, along with engineering consultation and custom solutions.

Why Manufacturers Matter in Rack and Pinion Systems

The performance of a rack and pinion setup is only as good as the engineering and production quality behind it.

1. Design Expertise

Manufacturers are involved in material selection, gear ratio calculations, tolerance planning, and other critical design aspects to ensure optimal performance.

Read also: Business Payments With General Interbank Recurring Order

2. High-Precision Machining

Using CNC gear-cutting, hobbing, and grinding tools, manufacturers ensure exact tooth profiles and perfect gear meshing.

3. Material Optimization

Depending on the application, manufacturers use materials ranging from carbon steel and aluminum to engineering plastics or stainless steel.

4. Advanced Surface Treatments

Processes like carburizing, nitriding, black oxide coating, and zinc plating enhance gear performance, life, and corrosion resistance.

5. Testing and Quality Assurance

Manufacturers conduct load testing, backlash inspection, and gear accuracy grading to meet industry standards and certifications.

Industries That Rely on Rack and Pinion Manufacturers

Automotive Industry

A reliable manufacturer ensures smooth handling, durability, and safety in vehicles.

Packaging and Conveyor Systems

In the material handling industry, rack and pinion drives power automated packaging machines, palletizers, and conveyor belts with high reliability.

CNC and Fabrication Machines

From plasma cutters to routers, rack and pinion drives allow precise control over cutting paths. Manufacturers must offer high accuracy and minimal backlash gears.

Construction and Heavy Equipment

Cranes, elevators, and lifting platforms use heavy-duty rack and pinion systems for vertical or horizontal travel under load.

Renewable Energy and Solar Tracking

Rack and pinion systems help align solar panels to follow the sun, enhancing energy capture.

Marine and Offshore

Manufacturers produce marine-grade rack and pinion systems for ships and offshore rigs.

Qualities to Look for in a Rack and Pinion Manufacturer

Choosing the right partner can have long-term effects on your project’s performance, safety, and cost-efficiency. Here’s what to look for in a rack and pinion manufacturer:

1. Industry Experience

They’ll understand your specific requirements better.

2. Engineering Support

A manufacturer who provides design consultation, prototyping, and technical drawings ensures a collaborative development process.

3. Customization Options

From gear pitch and tooth count to mounting style and material, customization is often key. A capable manufacturer will tailor every parameter to your need.

Manufacturing Process Overview

The rack and pinion gear manufacturing process includes several precision steps:

Step 1: Material Procurement

Raw materials like alloy steel bars or plastic extrusions are sourced based on strength, weight, and environmental needs.

Step 2: Gear Blanking

Materials are machined into blanks, typically through turning or milling.

Step 3: Gear Cutting

Using CNC hobbing or shaping, the tooth profiles are carved into the rack and pinion components.

Global Market for Rack and Pinion Systems

The global demand for rack and pinion systems is growing rapidly, driven by automation, robotics, and renewable energy. Markets in Asia-Pacific, Europe, and North America are investing heavily in high-performance motion systems.

Top-tier rack and pinion manufacturers are expanding their capabilities to include:

- AI-assisted design tools

- Robotic gear measurement

- Additive manufacturing for prototypes

- Environmental sustainability in production

Conclusion

In the expanding universe of industrial mechanics and motion control, the rack and pinion manufacturer is a crucial architect of modern efficiency. They don’t just create gears — they engineer solutions, power systems, and enable innovation.

From mass production of automotive steering systems to small-batch, high-precision parts for aerospace, rack and pinion manufacturers shape the way machines move, industries evolve, and technologies advance. Choosing the right manufacturer is not just about procurement — it’s about partnership, performance, and long-term reliability.