Vacuum Forming Manufacturer: Your Partner in Precision Plastic Solutions

Introduction

In the fast-paced world of industrial manufacturing, finding the right partner to deliver reliable, affordable, and high-quality plastic components is critical. One increasingly popular fabrication method is vacuum forming—a thermoforming process that allows the creation of lightweight, durable plastic parts at a relatively low cost. The companies that specialize in delivering these solutions are known as vacuum forming manufacturers.

This article delves into the world of vacuum forming manufacturing, exploring the process, benefits, applications, and how to choose a dependable vacuum forming manufacturer for your business needs.

Understanding Vacuum Forming

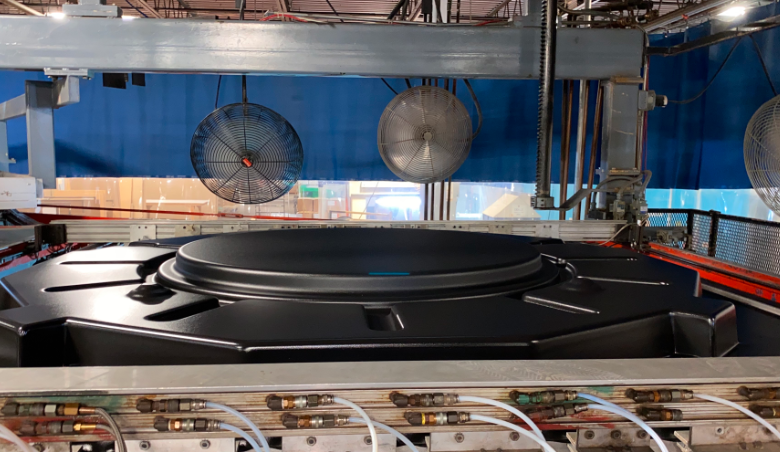

Vacuum forming is a simplified version of thermoforming where a plastic sheet is heated until pliable and then stretched over a mold. A vacuum is then applied to suck the plastic tightly against the mold, capturing the shape with precision. Once cooled, the formed plastic is trimmed and processed for use.

The process is efficient, cost-effective, and ideal for producing medium- to large-sized parts in limited production runs. It’s widely used in industries ranging from automotive and aerospace to retail and consumer packaging.

Role of a Vacuum Forming Manufacturer

A Vacuum forming manufacturer provides end-to-end solutions for businesses looking to prototype, mass-produce, or customize plastic components. These manufacturers have dedicated equipment, skilled technicians, and design teams to handle everything from material selection to mold creation, forming, and post-processing.

Whether it’s a custom dashboard panel for a vehicle, a housing cover for a device, or packaging trays for electronics, the right vacuum forming manufacturer can turn your design into a functional product with high accuracy.

Why Businesses Choose Vacuum Forming

1. Cost Efficiency

Tooling costs are significantly lower compared to injection molding. This makes vacuum forming attractive for small and medium production runs or rapid prototyping.

2. Fast Turnaround

The setup time is minimal, and once the mold is ready, the production process is fast. This results in shorter lead times and quicker delivery of finished parts.

3. Material Flexibility

A variety of thermoplastics can be used in vacuum forming, including ABS, PETG, PVC, HIPS, and polycarbonate. This allows manufacturers to tailor materials to match required properties like impact resistance, UV protection, or transparency.

Industries Relying on Vacuum Forming Manufacturers

- Automotive: Interior panels, bumper covers, trunk liners.

- Medical: Sterile trays, medical equipment housings.

- Retail: Custom display stands, product packaging.

- Food Service: Disposable trays, container lids.

- Agriculture: Seed trays, covers, irrigation panels.

- Electronics: Device enclosures, control panels.

Each industry has unique standards, and experienced manufacturers can adjust their processes to meet exact tolerances, certifications, and material requirements.

See also: China Aluminum Coil: Global Leader in Metal Supply

Steps Involved in the Vacuum Forming Process

A typical vacuum forming manufacturer follows a series of standard steps to ensure quality and consistency in their products:

Step 1: Concept and Design

Clients provide CAD files or product sketches. The manufacturer may assist in refining the design for manufacturability.

Step 2: Mold Creation

A mold (usually made of aluminum, wood, or resin) is produced based on the final design

Step 3: Material Selection

The right type and thickness of plastic sheet are selected, balancing performance needs and cost.

Step 4: Forming Process

The plastic sheet is heated in a forming machine and vacuumed over the mold to create the desired shape.

Step 5: Cooling and Trimming

The shaped part is cooled, removed from the mold, and excess material is trimmed.

Step 6: Finishing

This can include drilling, painting, logo embossing, or coating based on the client’s specifications.

Choosing the Right Vacuum Forming Manufacturer

Not all manufacturers offer the same level of quality, service, or technical capability

1. Experience and Track Record

Look for manufacturers with a proven history of delivering high-quality vacuum-formed parts. Their case studies or client portfolios can offer insight into their expertise.

2. Technology and Equipment

Modern machinery ensures precision and faster output. Ask about their forming machines, mold-making tools, and quality control procedures.

3. Material Knowledge

A competent manufacturer understands how different plastics behave under heat and vacuum pressure. Their guidance on material selection can significantly impact product performance.

4. Customization Capabilities

Your project may require unique features. Choose a manufacturer that offers customization, from mold design to color matching and branding.

5. Scalability

Ensure the manufacturer can handle your current needs and scale up production if your demand grows.

6. Communication and Support

Responsive communication and post-delivery support are crucial, especially when dealing with overseas or time-sensitive projects.

Global Outlook: Vacuum Forming and Manufacturing Trends

Vacuum forming is evolving with technological innovations and market shifts. Here are some emerging trends among top vacuum forming manufacturers:

- 3D Printed Molds: Faster and cheaper mold creation using additive manufacturing.

- Smart Automation: Integration of robotics and AI for forming, trimming, and packaging.

- Sustainable Plastics: Increased use of biodegradable or recycled materials.

- On-Demand Manufacturing: Low-volume, fast-turnaround production models for startups and design firms.

Manufacturers that embrace these trends are setting new benchmarks in quality and customer satisfaction.

Conclusion

In today’s manufacturing ecosystem, a skilled and reliable vacuum forming manufacturer can be a critical partner in product development and production. Offering cost-effective solutions, rapid prototyping, and high customization, vacuum forming stands out as a versatile plastic forming method across various industries.

Choosing the right manufacturer involves understanding your own project goals and aligning them with a partner who offers the right mix of technology, expertise, and flexibility. As more companies look for quick, scalable, and sustainable solutions, vacuum forming will continue to play a vital role—and the manufacturers who master it will lead the way.