Precision and Perfection: Unveiling the World of Injection Molding Services

Introduction

In the realm of modern manufacturing, precision and efficiency are paramount. Injection molding services epitomize these qualities, offering a seamless and versatile approach to producing a wide range of plastic components. This in-depth exploration delves into the realm of injection molding services, uncovering their core functionalities, technological advancements, industry applications, quality benchmarks, market dynamics, and future trajectories. By unraveling the intricacies of injection molding services, we unveil their pivotal role in shaping the manufacturing landscape and driving innovation across diverse sectors.

Essence of Injection Molding Services

At the heart of injection molding services lies a spectrum of crucial functions and capabilities that ensure the seamless production of high-quality plastic parts:

- Design Expertise: Injection molding services collaborate with clients from the conceptual stage, offering expertise in design optimization, material selection, moldability assessment, and production feasibility to achieve optimal outcomes.

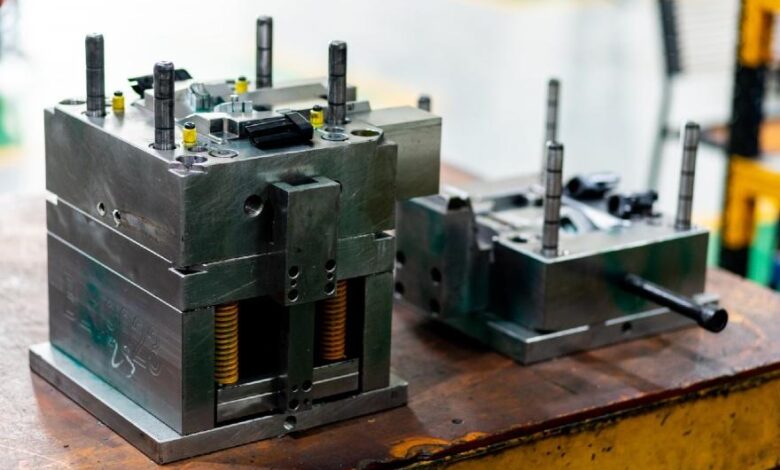

- Tooling Excellence: Services excel in tooling development, utilizing advanced CAD/CAM software, CNC machining, and mold fabrication techniques to create intricate and durable molds tailored to specific project requirements.

- Production Precision: Services operate state-of-the-art injection molding machines, maintaining tight process controls, and utilizing scientific molding principles to achieve consistent part quality, dimensional accuracy, and surface finish.

- Quality Assurance: Services implement stringent quality control protocols, conducting inspections, testing, and validation procedures to ensure adherence to industry standards, regulatory requirements, and customer specifications.

- Value-Added Solutions: Services offer value-added services such as secondary operations, assembly, finishing, packaging, and logistics management to provide comprehensive manufacturing solutions and meet diverse customer needs.

- Continuous Improvement: Services focus on Plastic Injection Molding Manufacturer continuous improvement initiatives, embracing lean manufacturing principles, process optimization, and innovation to enhance efficiency, reduce waste, and drive operational excellence.

Technological Advancements

Injection molding services harness cutting-edge technologies and innovations to deliver superior results and stay ahead in a competitive market landscape:

- Advanced Materials Handling: Services work with a wide range of thermoplastic, thermoset, and engineering-grade materials, leveraging material expertise, and compatibility to meet diverse application requirements.

- Precision Molding Techniques: Services employ advanced molding techniques such as gas-assisted molding, co-injection molding, multi-shot molding, and micro-molding to achieve intricate geometries, complex features, and enhanced part performance.

- Automation Integration: Services integrate automation, robotics, and Industry 4.0 technologies into production processes, optimizing cycle times, improving repeatability, and ensuring consistent part quality.

- Customization Capabilities: Services offer customization options, color matching, surface finishes, texture variations, and insert molding capabilities to accommodate unique design requirements and enhance product aesthetics.

- Environmental Sustainability: Services prioritize sustainability initiatives, incorporating eco-friendly materials, energy-efficient processes, waste reduction strategies, and recycling practices to minimize environmental impact and promote sustainability.

- Digital Connectivity: Services leverage digital connectivity, IoT-enabled monitoring, real-time data analytics, and remote diagnostics to create interconnected production ecosystems, enabling predictive maintenance, and operational efficiency.

Industry Applications and Impact

Injection molding services play a crucial role across diverse industries, contributing to innovation, efficiency, and product excellence:

- Automotive Sector: Services supply automotive components such as interior trim parts, exterior body panels, lighting systems, and engine components, supporting automotive manufacturers in enhancing vehicle performance, aesthetics, and functionality.

- Consumer Electronics: Services manufacture electronic enclosures, housings, connectors, switches, and device components for consumer electronics products, contributing to technological advancements, product durability, and user experience.

- Medical and Healthcare: Services produce medical device housings, surgical instruments, diagnostic tools, disposable products, and packaging for the healthcare sector, ensuring quality, reliability, and regulatory compliance.

- Packaging Solutions: Services create packaging solutions, containers, closures, caps, and bottles for food packaging, cosmetics packaging, pharmaceutical packaging, and industrial packaging, meeting diverse packaging needs and market requirements.

- Industrial Applications: Services supply industrial components, enclosures, housings, and mechanical parts for machinery, equipment, tools, and automation systems, supporting industrial operations and infrastructure development.

- Aerospace and Defense: Services manufacture aerospace components, aircraft interiors, avionics parts, defense equipment, and precision components meeting stringent aerospace and defense standards, contributing to aviation safety, reliability, and performance.

Quality Standards and Market Dynamics

Injection molding services adhere to stringent quality standards, certifications, and best practices to ensure product excellence, customer satisfaction, and market competitiveness:

- ISO Certification: Services maintain ISO 9001 certification for quality management systems, demonstrating commitment to quality, process control, and continuous improvement.

- Industry-Specific Compliance: Services adhere to industry-specific standards such as ISO/TS 16949 (automotive), ISO 13485 (medical devices), AS9100 (aerospace), and regulatory requirements for electronics, ensuring product compliance and market acceptance.

- Quality Control Measures: Services implement comprehensive quality control measures, including inspections, testing, dimensional checks, and validation processes, to verify part quality, functionality, and reliability.

- Market Dynamics: Injection molding services navigate dynamic market dynamics, including demand fluctuations, supply chain challenges, raw material availability, pricing trends, and global economic factors, to ensure business resilience and customer satisfaction.

Future Trends and Innovations

The future of injection molding services is characterized by ongoing advancements, digital transformations, and sustainability initiatives:

- Smart Manufacturing Integration: Services embrace smart manufacturing concepts, digital connectivity, IoT-enabled monitoring, and data analytics to create agile, connected, and data-driven production environments.

- Additive Manufacturing Synergy: Services explore synergies between injection molding and additive manufacturing (3D printing) technologies, enabling rapid prototyping, tooling fabrication, customization, and hybrid manufacturing solutions.

- Sustainable Innovations: Services innovate with sustainable materials, bio-based polymers, recyclable solutions, energy-efficient processes, and waste reduction strategies to address environmental challenges and meet consumer demands for eco-friendly products.

- Customization and Personalization: Services offer customization, personalization, and on-demand manufacturing services to meet individual customer needs, market trends, and niche product requirements.

- Supply Chain Resilience: Services enhance supply chain resilience, diversify sourcing strategies, adopt risk management practices, and leverage local manufacturing capabilities to mitigate global disruptions and ensure business continuity.

- Collaborative Partnerships: Services forge strategic partnerships, collaborations, and ecosystem alliances with technology providers, material suppliers, research institutions, and customers to drive innovation, co-create solutions, and address complex challenges in the manufacturing ecosystem.

Conclusion

Injection molding services embody the pinnacle of precision, efficiency, and innovation in modern manufacturing. Their advanced capabilities, technological advancements, industry impact, and commitment to quality position them as key enablers of progress and transformation across sectors.

By delving into the core functionalities, technological advancements, industry applications, quality benchmarks, market dynamics, and future trajectories of injection molding services, we gain a comprehensive understanding of their pivotal role in shaping the manufacturing landscape. As the industry continues to evolve, embrace digital transformation, and pursue sustainability initiatives, injection molding services will remain at the forefront of innovation, driving progress, competitiveness, and sustainability in the global manufacturing ecosystem.