Unveiling Efficiency: The Ingenious Technology of Oil-Less Air Compressors

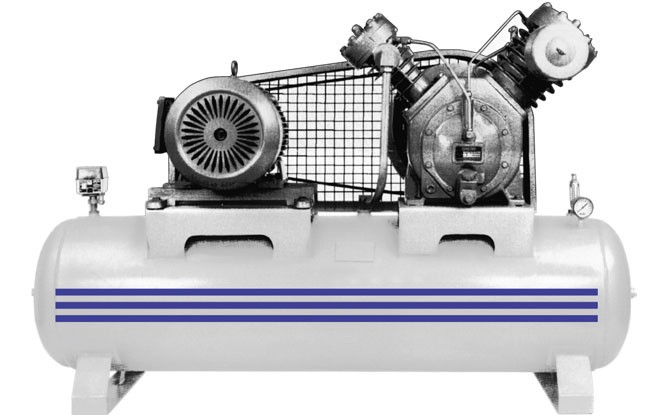

Oil-less air compressors represent a technological breakthrough in the realm of compressed air systems, offering clean, contaminant-free air without oil less air compressor the use of lubricating oils. In this comprehensive article, we delve into the workings, advantages, limitations, applications, and future prospects of oil-less air compressors, unlocking the secrets behind their efficiency and performance.

1. Introduction to Oil-Less Air Compressors: Oil-less air compressors, also known as oil-free or oil-less compressors, have gained widespread popularity across various industries due to their ability to deliver clean and oil-free compressed air. Unlike traditional compressors that rely on lubricating oils for smooth operation, oil-less compressors eliminate oil contamination, making them ideal for applications where air quality is critical.

2. The Working Principle of Oil-Less Air Compressors: The working principle of oil-less air compressors involves several key components and processes:

- Air Intake: Ambient air is drawn into the compressor through an inlet filter, removing impurities and ensuring clean air intake.

- Compression Stage: Inside the compressor, air is compressed using non-lubricated components such as Teflon-coated pistons, self-lubricating polymers, or specially treated surfaces. This eliminates the need for lubricating oils during the compression process.

- Cooling System: To prevent overheating during compression, oil-less compressors employ efficient cooling systems, such as air-cooled or water-cooled designs.

- Filtration and Purification: After compression, the compressed air passes through advanced filtration and purification stages to remove contaminants, moisture, and oil traces, ensuring clean and contaminant-free air output.

- Oil-Less Operation: Specialized materials, coatings, and sealing mechanisms are used to achieve oil-less operation, preventing oil from entering the compression chamber or contaminating the compressed air.

3. Advantages of Oil-Less Air Compressors: Oil-less air compressors offer numerous advantages that make them indispensable in various industries:

- Clean Air Quality: Suitable for applications requiring high air purity standards, such as medical facilities, laboratories, pharmaceuticals, and electronics manufacturing.

- Lower Maintenance: Elimination of oil changes and associated maintenance tasks reduces downtime, operational costs, and the risk of oil-related issues.

- Environmental Friendliness: Minimized oil discharge into the air stream contributes to environmental sustainability and compliance with regulatory standards.

- Versatility: Oil-less compressors are versatile and can be used in a wide range of applications, from small workshops to large industrial facilities.

4. Limitations and Considerations: While oil-less air compressors offer significant advantages, it’s essential to consider their limitations and factors to ensure optimal performance:

- Initial Cost: Oil-less compressors may have a higher initial cost due to specialized components, coatings, and manufacturing processes required for oil-less operation.

- Energy Consumption: Some oil-less compressors may consume more energy compared to oil-lubricated compressors, especially if they require additional cooling systems or non-lubricated components that experience higher friction.

- Capacity and Size: In certain applications, oil-less compressors may have limitations in terms of capacity and size compared to oil-lubricated compressors, impacting their suitability for heavy-duty operations.

- Maintenance: While oil-less compressors eliminate oil-related maintenance, they may require more frequent maintenance of non-lubricated components, such as seals and bearings.

5. Applications of Oil-Less Air Compressors: Oil-less air compressors find extensive use across a wide range of industries and applications:

- Healthcare: Medical air supply, dental equipment, surgical tools, and patient care equipment in hospitals and clinics.

- Pharmaceuticals: Cleanroom environments, drug manufacturing, and packaging processes requiring contaminant-free air.

- Food and Beverage: Air supply for food processing, packaging, and storage to prevent contamination and maintain product quality.

- Electronics: Precision manufacturing, cleanroom environments, semiconductor fabrication, and assembly of sensitive electronic components.

6. Future Trends and Innovations: The future of oil-less air compressors is marked by continuous advancements and innovations aimed at enhancing performance, efficiency, and sustainability:

- Energy Efficiency: Integration of energy-saving technologies such as variable speed drives, smart controls, and energy recovery systems to optimize energy consumption.

- Material Innovations: Development of advanced materials, coatings, and lubrication technologies to improve durability, reduce friction, and extend compressor lifespan.

- Digitalization: Integration of IoT connectivity, remote monitoring, predictive maintenance, and real-time performance analytics for proactive system management and optimization.

7. Conclusion: Oil-less air compressors have revolutionized the compressed air industry by offering clean, efficient, and reliable compressed air solutions. Their innovative working principle, coupled with numerous advantages and ongoing innovations, positions them as indispensable assets in modern industrial settings. As industries continue to evolve, oil-less air compressors will play a crucial role in driving efficiency, sustainability, and performance, paving the way for a greener and more efficient future.